Scientific program

2020 expedition

Phase 1: Sampling

Part of our work involves taking seawater samples to collect microplastics. Depending on the partners and their needs, the nets used and the protocols followed are not the same.

In the water column

The protocol for sampling in the water column has been validated by the 2017, 2018 and 2019 expeditions. It uses a closing net which can be dove up to 150 m deep. It is then trawled back to the surface. A mechanism allows us to close the net at any depth. Expedition 2020 uses this protocol to sample micro-plastic between 30 m and 80 m depth. The micro-plastics recovered measure between 100 μm and 5 mm.

On the surface

The manta net allows sampling on the surface of the water, in the first 15 cm of the water column. Throughout the sampling period, the net must be towed by the moving boat at a speed of between 3 and 5 knots.

In 2022, the crew embarked 2 different manta nets. One has a mesh of 125 µm (LNE - AgroParisTech) and the other* of 300 µm (Oceaneye).

*This net was lent to us by the Swiss Cetacean Society

Sampling of nanoplastics

In Depth: Niskin Bottles

Sampling of nanoplastics is done using four Niskin bottles . These are sampling bottles, used to take water from a given depth, by lowering them at the end of a cable into the sea.

For SEA Plastics, in 2021, four Niskin bottles were immersed in the water column, then brought back on board, where the samples passed through sieves of increasingly fine mesh, to then be filtered on a microfiber support of glass that will keep all particles between 700 nm and 50 µm.

Glass microfiber media in 2021 made sample analysis difficult. In 2022, tests will perhaps be carried out with a support of a different nature.

.jpg)

Embedded experiences

In 2022, the crew decided to conduct their own experiments aboard the boat. These experiments carried out in environmental conditions aim to study two issues related to microplastics:

the aging of microplastics in the marine environment

the transport of pollutants by microplastics

Setting up these experiments required phases of consultation, design, prototyping, testing and industrialization before the start of the expedition. Once on board, new tinkering sessions, tests and adjustments were necessary. Laboratory tests and the reality on the ground are not the same thing!

Aging of microplastics under environmental conditions

In the environment, plastic particles are subject to many mechanical (waves, current), physical (UV, temperature), chemical (oxidation, hydrolysis) and biological (biodegradation by microorganisms) constraints.

Over time, plastics then undergo structural modifications (abrasion, cracks, fragmentation, alteration of crystallinity, etc.) but also chemical ones (phenomenon of adsorption and desorption of molecules). Biofilms can also form on the surface of plastics.

The aging of plastic is a real problem because it multiplies the dangers associated with plastic pollution: fragmentation of particles into micro- and nanoplastics, promoting their dissemination and increasing ingestion by living organisms; formation of biofilms and transport of pathogenic and/or invasive species; increase in the capacity for adsorption of pollutants and desorption of additives in the marine environment.

1. Design

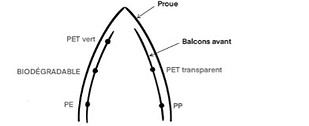

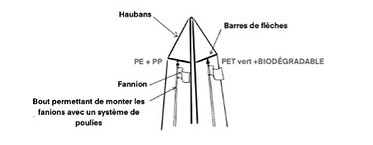

We have chosen to study the aging of four different plastics. Polyethylene (PE) and polypropylene (PP) are commonly found in the marine environment and few studies have investigated their aging under environmental conditions. Polyethylene terephthalate (PET) is a very resistant plastic according to the literature. This is why we chose to take him as a negative control. Finally, we chose a biodegradable polymer (potato starch) with low resistance as a positive control.

Before shipping, strips were cut by hand from PE, PP, PET and biodegradable plastic.

Again, not everything goes as planned when you are in the field.

Initially, 3 batches made up of 4 types of plastic had to be immersed in seawater for the duration of the expedition at three different depths.

We had imagined an experimental design consisting of towing a chain at the back of the boat, on which would have been fixed three protective metal baskets containing the plastic strips. A batch of strips would also have been placed on the deck of the boat.

2. Positioning on board

Unfortunately, this protocol cannot be followed in this way. Indeed, towing a 10m chain is only possible offshore. However, the total cumulative duration of our stopovers in port being too long, the duration of immersion in the water of the strips would have been too short to detect significant modifications of their structure.

We have therefore chosen to change the exposure conditions for batches of strips:

Immersion in sea water between the surface and 2m deep

Exposure to the open air with spray : on the deck of the boat

Exposure to the open air without spray : at the top of the mast of the boat

Transport of pollutants by microplastics

It has been shown that microplastics (particles < 5 mm) present in the ocean are capable of transporting pollutants . These compounds can come from the specific composition of the plastics (chemical additives giving properties to the plastic, added during its manufacture). But it can also be chemical compounds present in the ocean (hydrocarbons, pesticides, drug residues, persistent organic pollutants, endocrine disruptors, etc.) which are adsorbed on microplastics, i.e. which are y fix.

Microplastics are the supports of choice : all hydrophobic compounds (which cannot form a bond with water) tend to attach themselves to all residues which are not water molecules. Other so-called "amphiphilic" compounds attach to it, but in a more fragile way.

This transport of pollutants represents a danger for the health of marine organisms : during the passive ingestion of microplastics and under the effect of digestive fluids, pollutants (in particular amphiphiles) can be released into the tissues of living organisms and disrupt their major functions (growth, reproduction, respiration, etc.).

1. Design

In order to study the transport of micropollutants by microplastics, we imagined an experimental design consisting of immersing “virgin” microplastics, of different but known natures, in seawater during our expedition. These microplastics would be grouped in small boxes, themselves contained in jars.

SPECIFICATIONS

Boxes should be:

filters (water must pass through) and contain microplastics (which must not come out)

resistant (to withstand shocks)

identifiable as to the nature of the microplastics they contain

their size must allow them to contain 2.5 g of microplastics

Jars should be:

crossings of a uniform flow of seawater

there should be no open water surface

supplied with sea water offshore and in the ports (the water in the ports being overpolluted, a “buffer” circuit must be set up)

Filter boxes and microplastics

Many discussions were necessary to determine the most favorable system and materials. Several ideas have emerged for the manufacture of filter boxes:

Idea 1: pierce the lid of the boxes with a “fakir carpet” type nail system.

Idea 2: place a metal mesh on the opening of the boxes with screws

Idea 3: flatten a metal mesh with a cylinder a little larger than the height of the box and forcefully screw the cap onto the screw thread.

Prototypes were therefore designed and tested.

In the end, the prototype with the cylinder was chosen.

It was then necessary to move on to industrialization : there were 300 boxes to manufacture. The cylinders were able to be manufactured at EPFL's ATMX workshop from aluminum tubes.

The boxes were cut with an awl, the lattices and the metal fabric with cutting pliers.

We also had to think about the massive production of microplastics . Some of the microplastics were grated or cut from macroplastics (pipes, bottles, etc.). For some pieces that were still too big, cryogenization (liquid nitrogen, -150°C) was necessary, followed by grinding and sieving.

We chose to study microplastics commonly found in the marine environment: polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET) and polyvinyl chloride (PVC). We will also study tire particles (little studied in environmental conditions and among the first sources of primary microplastics).

jars

A total of six jars will be used on board:

three of them will serve as a buffer : we will fill them offshore before our arrival in each port, in order to be able to renew the water in the experimental jars during our stopovers

three “ experimental ” jars will contain the filter boxes filled with microplastics

jar A: contains the PVC and PS boxes

jar B: contains the PET and PP boxes

jar F: contains tire particles

2. Positioning on board

Once the jars were on board, we had to think of a way to feed them with a flow of seawater. To do this, we used an existing through-hull to take advantage of an opening on the pontoon. The fresh water system was connected to this through-hull, with a valve already in place and connected to the pump. (This fresh water pipe allows the supply of water at the quay, and at sea to sprinkle the fresh water bridge.) In the same place, a pipe from the salt water circuit connected to this same pump was condemned. We restarted it and connected it to the through-hull with a T and a double-valve system.

The three experimental jars could then be connected to the salt water circuit via a nurse.

The pump will not be able to run continuously on the high seas, its electricity consumption being too high. It therefore operates intermittently to allow regular renewal of the water.